CUSTOMIZED TEST AND INSPECTION SYSTEMS

FLEXIBLE. COST-EFFICIENT. ANTICIPATION

As a specialist in electronics and electrical engineering, habemus! develops, designs and builds customized test and inspection systems. Due to many years of experience in the field of electronics development, test engineering and test automation, we are able to realize cost-optimized test and inspection systems within a very short time.

When developing and manufacturing a test and inspection system, quality, cost-effectiveness and reliability are of highest importance. Quality, cost-effectiveness and reliability characterize the thinking and acting of our employees. A continuous improvement of already existing solutions is also a matter for us.

We supply both single pieces and small series for use in development and manufacturing. As a partner in electronics development and manufacturing, we can handle the full or partial development of test and inspection systems. As a solution and system specialist, we develop flexible and visionary solutions.

INDIVIDUAL TEST AND INSPECTION SYSTEMS

habemus! develops customized test systems for electronic assemblies. You receive the testing concept, software and hardware from one source. Our customers particularly appreciate our many years of experience in electronics development and manufacturing. They also rely on our comprehensive and cross-sector know-how

TEST SOFTWARE

For many years we have relied on LabVIEW from National Instruments for our testing software. We offer a kind of modular system, which guarantees a fast, clean and cost-optimized implementation. Our software structure offers maximum flexibility and allows easy integration of customer requirements.

- Program architecture with a clear framework for fast development possibilities

- Modular program parts, for high reusability in future software solutions

- Program code according to NI LabVIEW style guides, for comprehensibility and easy maintainability

- Use of NI queue-based producer-consumer architectures for simplicity, easy parallelization of program sequences, and independence between program parts

- Compact block diagrams with clean wire guidance without code overlays

- Structured, attractive front panels for good usability

- Prevention of race conditions by using functional global variables, queued message handlers and event structures

- In addition to the complete source code, you will also receive a software package with an exe file and installer for easy use on third-party systems.

MEASURING TECHNOLOGY

In addition to the standard PXI components from National Instruments, we rely on renowned standard measuring and power supplies from Keysight, Keythley and Rhode & Schwarz. If requested by the customer, devices from all manufacturers can also be used.

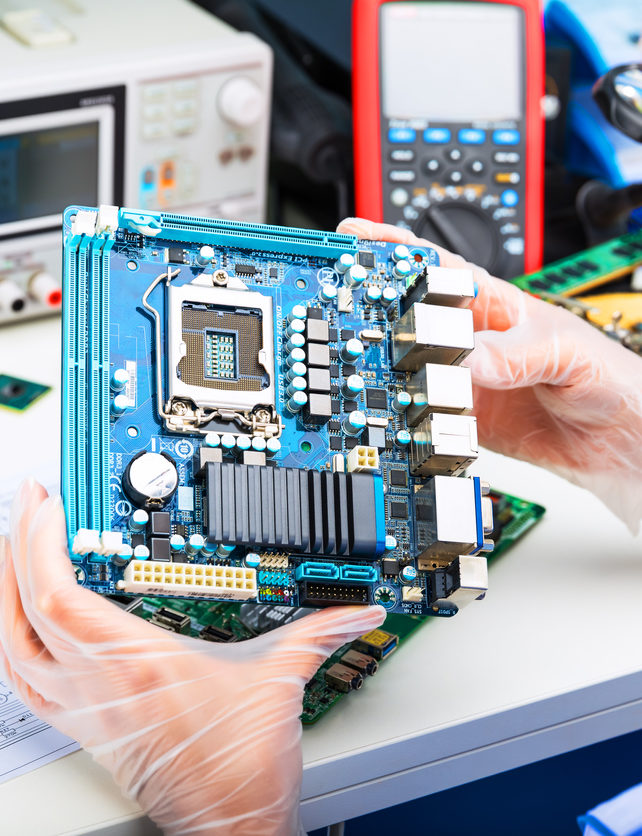

TEST HARDWARE

We develop individual interface PCBs and relay cards for use in our test systems. These are used for simple connectivity of the measurement technology and the test objects. The test objects to be tested are taken up in a needle adapter system from ATX. This is a manual adapter. The assemblies are inserted into the adapter on the board carrier plate. The test sequence starts automatically when the cover is closed.

FUNCTIONS

- Function test of electronic assemblies

- Inline programming of microcontrollers

- Adjustment / calibration of measuring inputs

- Use of camera systems for display or LED identification

- Traceability of the test items via code entry and database entry

- Creation of test reports

FEATURES

- CE marking with declaration of conformity

- Service Level Agreement (SLA)

- Machine Capability Analysis (MCA)

OUR TESTING SYSTEMS ARE DESIGNED TO MEET THE REQUIREMENTS OF OUR CUSTOMERS

OUR TOOLS IN THE DEVELOPMENT OF TEST AND INSPECTION SYSTEMS

LabVIEW

TEST AND INSPECTION SYSTEMS FOR A WIDE RANGE OF APPLICATIONS

We will be happy to work with you to develop a test concept for the optimum functional testing of your assemblies: we would also be happy to develop an individual test system for you.

Contact us to arrange a first informal meeting – we look forward to your request!

CONTACT